The imaging of the same item in different security inspection machines may be very different, which is an important reason for the difficulty in improving the accuracy of the intelligent security inspection identification system, and the difficulty in solving the problems of compatibility and adaptability.

To explain this problem, let's start with the process of generating X-ray images.

1. From detector signal to RGB image

During the security check, passengers place their luggage on the conveyor belt of the security inspection machine. The luggage enters the security inspection machine along with the conveyor belt, triggering the ray source to emit X-ray beams. The X-ray beam penetrates the luggage and falls on the detector, and the detector will collect. The ray photons are converted into measurable high and low energy data, and RGB security images are generated after complex processing and operations.

In the process of security inspection image generation, the data output by detectors of different models and years of use is different, and the data processing, image processing, geometric correction, and coloring schemes of different security inspection machine brands are different, which will bring about huge differences in X-ray images.

2. The nightmare of image discrepancy and model recognition

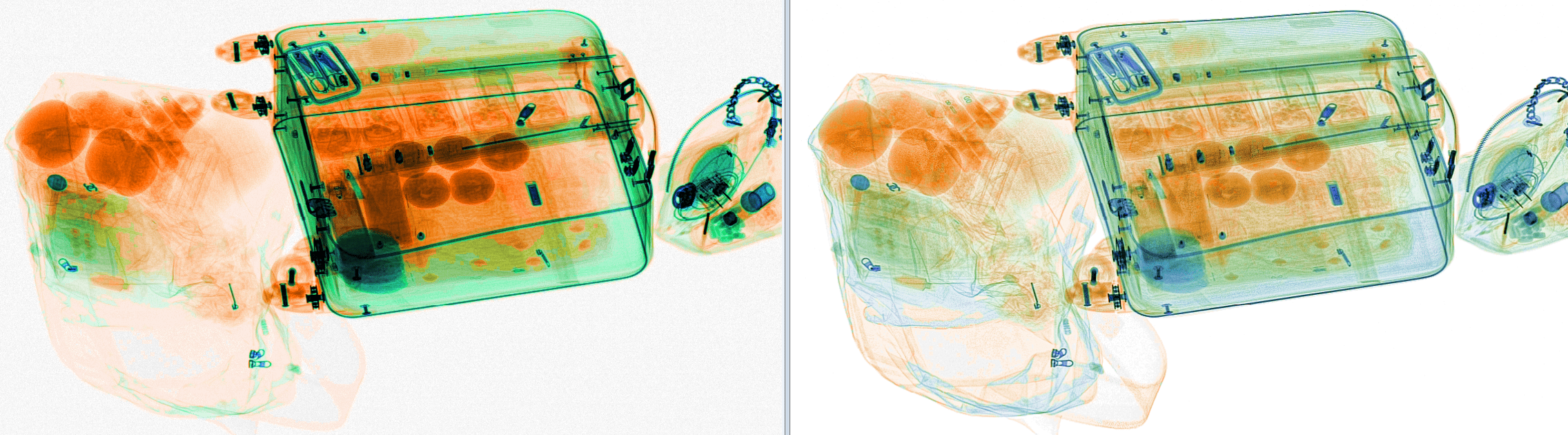

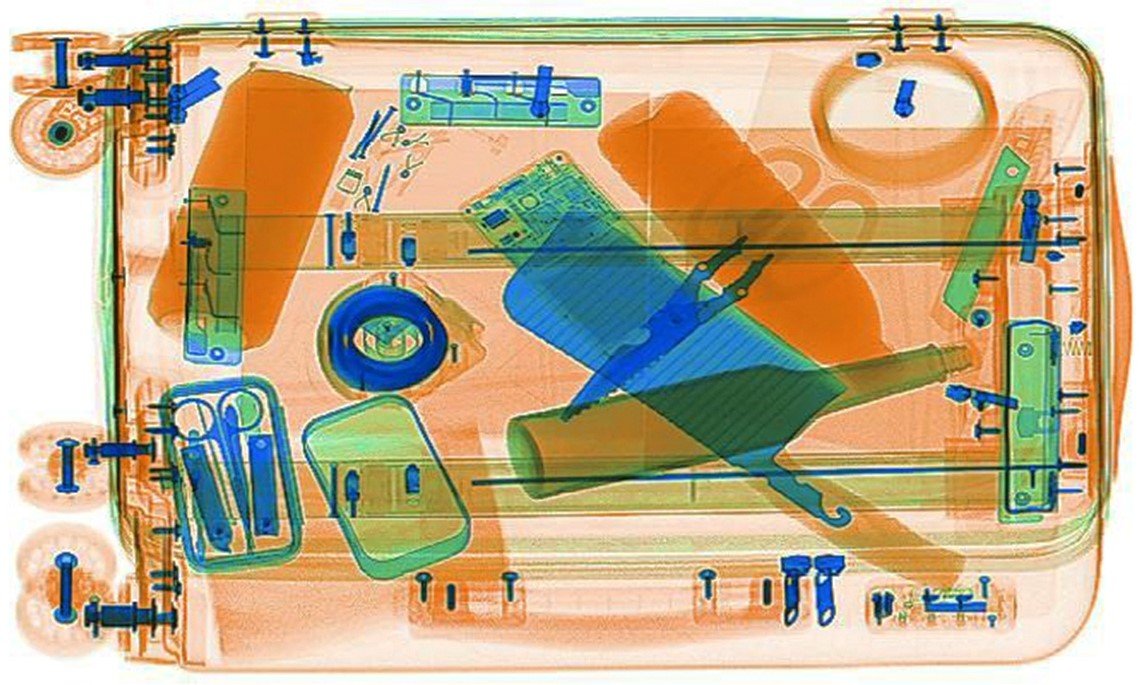

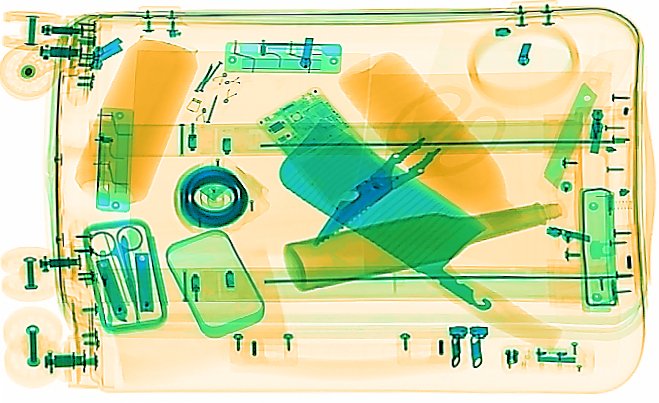

The images generated by different X-ray security inspection machines are different in terms of color matching, pixels, geometric deformation, etc. For the deep learning model, images with slightly different key information such as color and shape may be two completely different images, which need to be re-learned.

(Imaging of the same baggage under different X-ray security screening machines)

The deep learning model lacks sufficient generalization ability, and it is difficult to identify images with great differences. Therefore, the difference of X-ray images will lead to problems such as low model learning efficiency, difficulty in model training, and difficulty in improving the recognition accuracy.

3. Advantages of the underlying data identification scheme of the security inspection machine

In response to the problem of intelligent identification caused by differences in X-ray images, Safeagle Technology has pioneered the identification scheme of the underlying data of the security inspection machine, which is modeled and identified by acquiring the underlying data of the security inspection machine.

The advantage of this solution is that the underlying data of different brands of security inspection machines have little difference and is easy to calibrate. It can be processed to form a unified standard X-ray image, which is easier for deep learning models to learn and identify, which can greatly improve the efficiency of model training and effectively Improve the accuracy of model recognition, completely solve the problems of system compatibility and adaptability, and accurately identify various liquid components.

From the perspective of the general environment, the current development of security inspection products is of great significance to the economic and social construction of various countries. It is worth looking forward to how the future will be.

Why is the accuracy of the intelligent security inspection and identification system difficult to improve? - Safeagle

Fill out more information, We will get back to you within 24 hours.

4F.,Bldg. B, Jin Hao Pioneer Park, No.9 Dafu Industrial Zone, Aobei Community, Guanlan St., Longhua Dist., Shenzhen, R.P.China

Sales@Safeagle.com

Telephone : 86-0755-82373580

Business Phone : 86-0755-82373580

Work Time :9:00-18:30(Beijing time)